Product Parameter

| Model NO. | S11M |

| Cooling Method | Oil-immersed Type Transformer |

| Winding Type | Multi-winding Transformer |

| Certification | ISO9001-2000, ISO9001, CCC |

| Usage | Rectifier Transformer, Combined Transformer, Power Transformer, Distribution Transformer |

| Frequency Characteristics | High Frequency |

| Shape of Core | Ring |

| Rated Capacity | 30-2500kVA |

| Voltage Combination | High Voltage Range & Low Voltage Range |

| Standard | GB/T6451-2008 |

| Vector Group | Ydn0 or Dyn11 |

| Delivery | 15~20days After Deposit |

| Control | Scm Control |

| Iron Core | Crystal Grain-Oriented Silicon-Steel Sheet |

| Certificate | CE & ISO 9001 |

| Transport Package | Wooden Case |

| Specification | S11M |

| Origin | Wenzhou, Zhejiang |

| HS Code | 8504330000 |

| Production Capacity | 1000PCS Per Month |

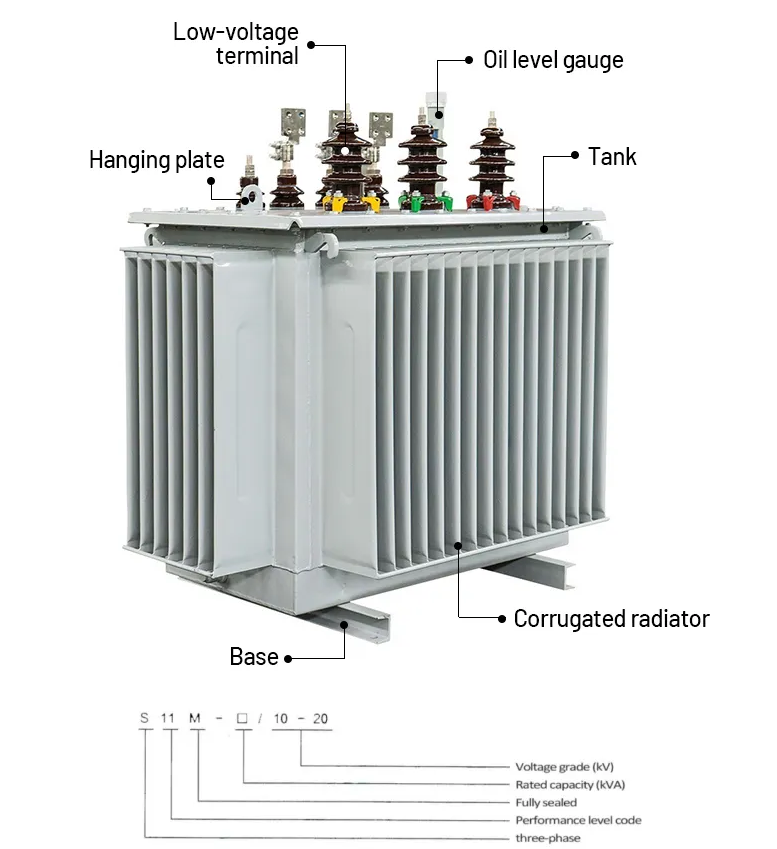

Iron core:

the iron core is made by crystal grain-oriented silicon-steel sheet; GEORG cross cut shear (made in West Germany) is adopted to cut the silicon-steel sheet with a 45°joint seam;fold the sheet into a multistage roll cross-section to reduce the noise and power consumption.

Coil:

cylinder type for high voltage; cylinder type or foil type for low voltage;this can increase the ability to resist short circuit and strike; and the distribution of magnetic path is more rational.

Oil tank:

the oil tank is made by fine cold-rolled steel sheets; GEORG corrugation oil tank production-line is adopted; to meet environmental needs, then, antiseptic coating material is applied on the surface, which can meet the requirements for petroleum and chemical industry (much oil stain and many chemical substances). In addition, the corrugations not any possess heat radiation function, but also meet the requirement for oil expansion and oil contraction trader normal performance. The iso lation from air guarantees a low aging speed of oil and a long life expectancy of transformer.

Insulation structure:

oil-immersed distribution transformer adopts A-level insulation structure; high voltage coil and low voltage coil are concentric; the space between coils is cardboard sleeve small oil clearance oil partition structure.

Product specification

- High – Voltage Adaptability: It can handle a wide range of input voltages, making it suitable for various power grid conditions.

- Large Capacity: Capable of handling significant power loads, ensuring stable power supply for industrial, commercial, and residential areas.

- Reliability: The oil – immersed design and high – quality materials guarantee long – term, trouble – free operation, reducing maintenance frequency.

Workshop

Production Process

- Raw Material Inspection: Before production, all raw materials, including silicon steel sheets for the core, copper or aluminum wires for windings, and insulating oil, undergo strict quality inspection. This ensures that only materials meeting high – quality standards are used in the manufacturing process.

- Core Manufacturing: The silicon steel sheets are cut into precise shapes according to design requirements. These sheets are then stacked and assembled to form the three – phase magnetic core. Special techniques are employed to reduce the air gaps between the sheets, which helps to minimize magnetic leakage and improve the transformer’s efficiency.

- Winding Wrapping: The primary and secondary windings are carefully wound around the core. The winding process requires high precision to ensure the correct number of turns and uniform distribution of the wire. Advanced winding machines are used to achieve consistent quality and accuracy.

- Insulation Treatment: After winding, the transformer undergoes an elaborate insulation treatment. The windings are impregnated with special insulating materials and then baked to enhance their insulation properties. This step is crucial for preventing electrical breakdown and ensuring the long – term reliability of the transformer.

- Overall Assembly: The core with windings is placed into the transformer tank, and then high – grade insulating oil is filled. All components, such as bushings, radiators, and oil conservators, are installed according to strict assembly standards.

- Factory Testing: Before leaving the factory, each transformer is subjected to a series of comprehensive tests, including insulation resistance tests, turns ratio tests, and load – loss tests. These tests ensure that the transformer meets all relevant national and international standards.

Certification

FAQ:

1. What are the main products of your company?

We specialize in the production and supply of power transformers, distribution transformers, dry-type transformers, pad-mounted transformers, and single-phase transformers.

2. When will you deliver the goods?

Our production timeline ranges from 45-60 days, contingent on the specifics of the buyer’s order.

3. Can you provide samples?

Unfortunately, we are unable to provide samples free of charge.

4. May I have your catalogue and price list?

Absolutely. Please contact us to obtain our comprehensive catalogue and detailed price list.

5.Can your products be customized?

Yes, we excel in producing and processing products tailored to your precise requirements.